VACUUM DEEP FRYING AND ITS ADVANTAGES

The main idea of this article is to explain what the vacuum frying process is, in which it differs from traditional and illustrate the benefits this technology brings to manufacturers. The vacuum dryer and deep fryer is suitable for various products: vegetables, fruits, meat, fish and flour products.

Properties of atmospheric fryers

Classical atmospheric deep fryers are used in the food industry to prepare a wide range of foods.

Such deep fryers are used in continuous automated lines for mass production of snacks and desserts. The products are immersed in boiling oil and deep fryed at high temperatures. This treatment, in addition to direct cooking, drains the product, absorbs oil and forms a crust on it.

In deep fryers, deep frying takes place – up to 180 ° C, the products are saturated with oil before they are finished and a crunchy crust is formed – a typical feature of fryed products. However, a similar processing carries a number of drawbacks that impair the quality of the final product.

- High oil content – up to 40%

- Product surface black

- Formation of carcinogenic substances

- The oil becomes hot, acquiring a specific odor and unpleasant taste

- The product kills nutrients, fades and loses its taste

- High level of acrylamide in the product – occurs at temperatures above 120 ° С

It is also important to mention the economic shortcomings of atmospheric deep fryers:

- Frying process duration

- High energy consumption

- Frequent oil change

Given the proven relationship between food consumption and human health, consumers carefully choose foods and often prefer healthy eating. One of the qualities of concern to the consumer is the high level of oil (fats). High fat products are associated with a range of problems that affect human health and lead to diseases such as:

- obesity

- Risk of cancer

- Risk of Type 2 Diabetes

- Increased likelihood of cardiovascular disease

Technologies aimed at reducing human health risks are used to produce modern industrial deep fryers. For example. an improved oil filtration system is used to extend its life. However, this is not enough to avoid all the problems associated with deep frying.

Why vacuum fryers are better

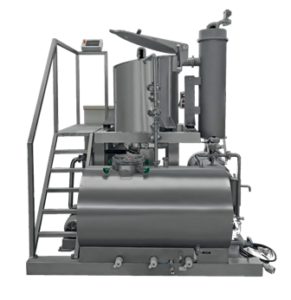

Vacuum deep fryers – an alternative way of preparing products at low pressure and low temperatures. It has been proven that the vacuum used speeds up the production process, making snacks useful and less dangerous to health. Deep frying with this technology can be described as a process of drying and cooking with hot oil. The product processing process looks like this:

The product is placed in a special pressurized container containing a deep fryer. The vessel connected to the vacuum pump is empty. At this stage, air and excess moisture are removed from the pores of the product. Next, the product is immersed in oil and fryed for the desired time, then rising. The pressure in the vessel returns to atmospheric and the product is removed from the fryer. Sometimes, in order to more effectively remove oil from the product, centrifugation is performed before the pressure in the vessel is restored.

Under vacuum conditions, water is removed from the product in a short time. This speeds up the product processing process, therefore the vacuum fryer has higher productivity than atmospheric. When the oil does not penetrate into the open pores of the product, the finished snack will contain up to 7% oil – compared to 40% of the content of conventional processing!

The low pressure at which the product is processed in a vacuum fryer allows deep-frying of snacks at low temperatures – from 85 ° C to 120 ° C. The oil is free of carcinogenic substances, stays fresh longer and consumes less than atmospheric deep fryers.

When frying at low temperatures, the product retains its natural color, taste, smell and nutrients. Vacuum deep frying transforms fruits and vegetables into healthy snacks, which are very popular and become a quality alternative to traditional chips.

The advantages of a vacuum fryer can be divided into two types:

Economical and qualitative

Vacuum deep frying makes it possible to create light snacks and meals with high added value at a low cost of electricity and other resources compared to traditional deep frying, giving the plant owner a competitive advantage.

Economic advantages:

- Relatively fast product frying: high productivity and low energy costs

- Oil saving – oil lasts longer fresh, does not burn, has no flavor of the last fryed product

- Fewer flavors and flavor enhancers are needed

- A competitive product in the snack and food market

A product made in a vacuum fryer is competitive because:

- Low oil content – up to 7%

- Appealing color of the product – close to natural, product does not darken and no black spots on the surface

- Oil does not burn – it does not add unwanted odor and taste to the product

- Maintains useful properties in the product

- Acrylamide-free – 94% less in product than in fryer

- Without carcinogenic substances

* The final product obtained by deep-frying is:

- helpful

- economic

- tasty

- requested

- Innovative